Safety at the

push of a button

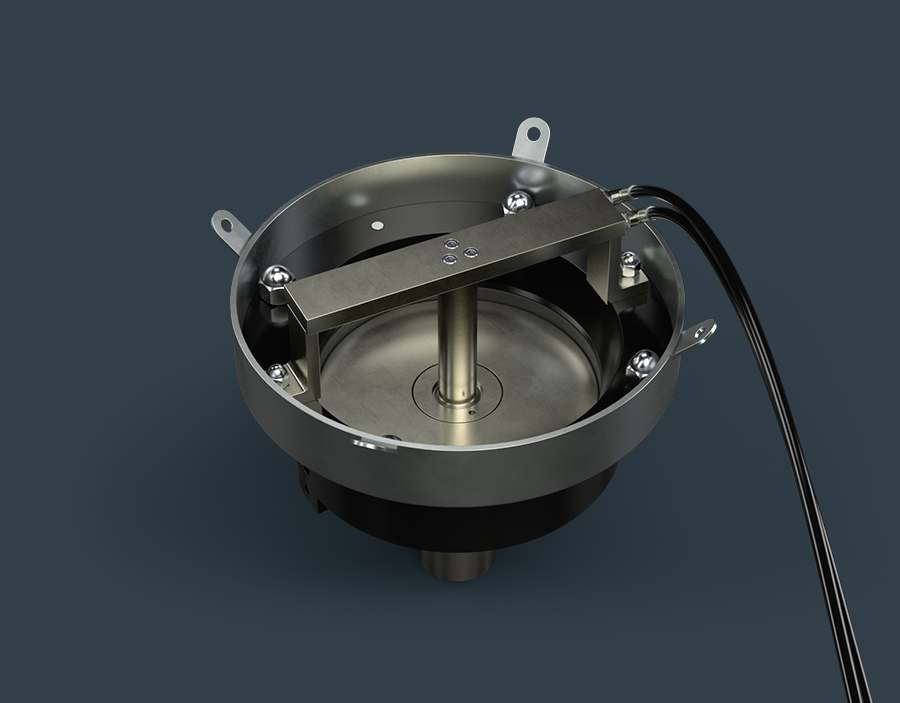

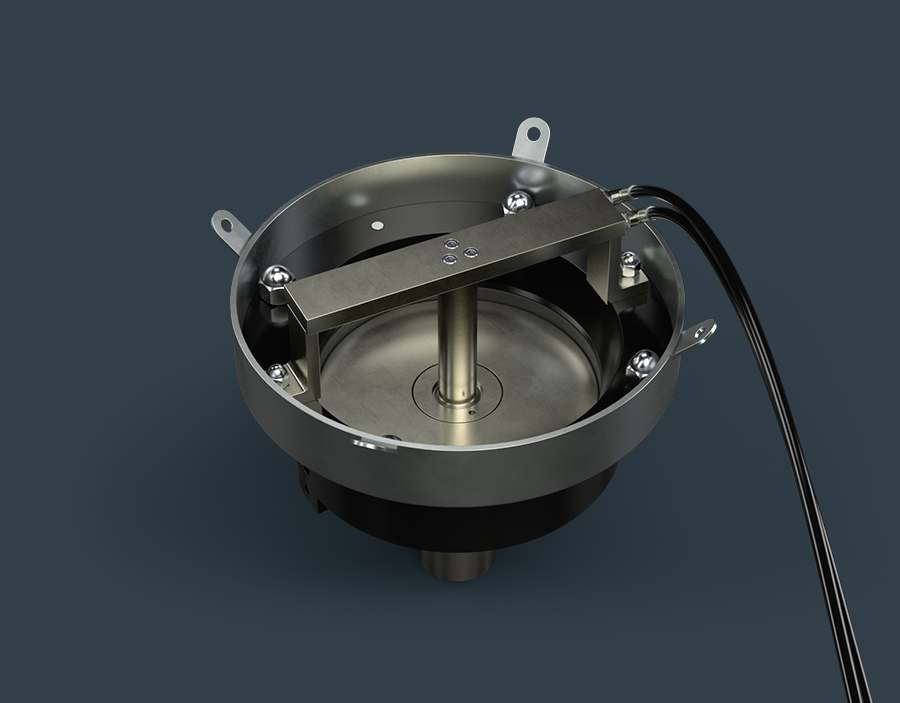

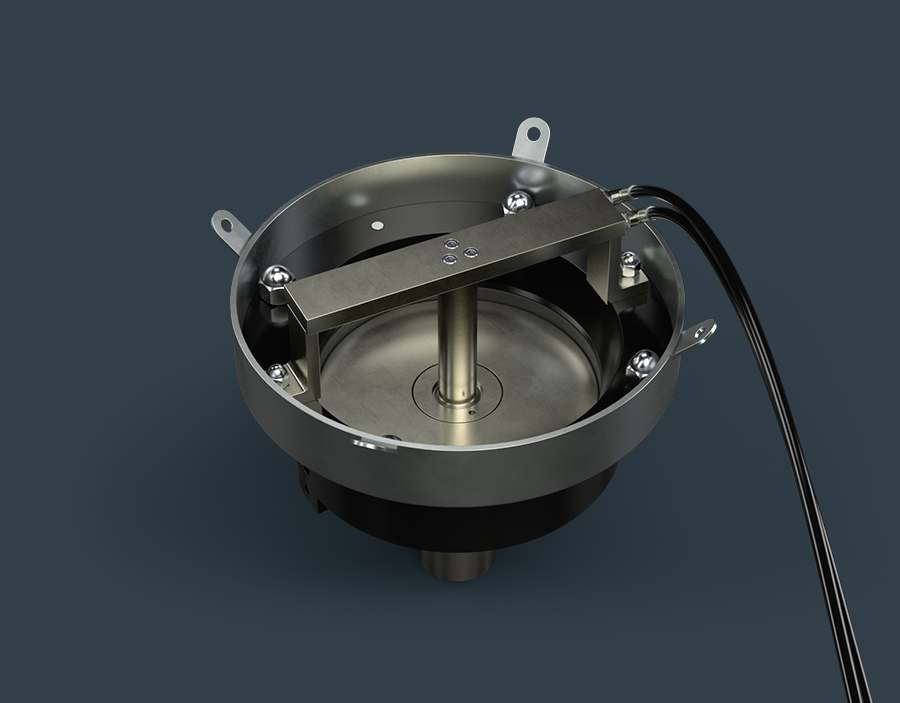

A.S.K. 450 and

A.S.K. 250

A.S.K. 450 and

A.S.K. 250

The valve is operated by compressed air and can be set to the position OPEN/CLOSED at the touch of a button.

Suitable for all common floor, yard and street drains: 500 x 500 mm (type 450) and 500 x 300 mm (type 250).

Special sizes or custom-made products available on request.

The A.S.K. has been used for many years in all industries that work with substances hazardous to water. Thanks to the materials used and the high-quality workmanship, annual maintenance is sufficient to ensure the functionality of the valve.

The valves are DIBt-approved and comply with the requirements of the ATEX directive according to 94/9/EC

Contact one of our service representatives now:

Our A.S.K. with automatic operation can be hermetically sealed simply by pressing a button, even from greater distances.

Our A.S.K. with automatic operation can be hermetically sealed simply by pressing a button, even from greater distances.

It also possible to connect several gullies in series and operate them simultaneously.

We recommend our manual A.S.K. to upgrade your existing sewer system. It is simple to install in just a few steps.

Needless to say, our automatic A.S.K. can also be retrofitted in an existing sewer system. Four holes and special concrete dowels are normally sufficient to fasten the gully safety valve in the sewer inlet. A sealing compound (Sikaflex) is used to make the valve impermeable to liquids. Finally, a leak test is performed.

In most cases our manual A.S.K. is suitable for existing sewer inlets. Automated and mechanical models are equally suitable for new sewer systems.

The automated A.S.K. is controlled with compressed air and via a control panel. Compressed air is supplied underground to the A.S.K. and the valve plate is opened or closed at the push of a button. When the pressure drops in the pneumatic system, the weight of the valve plate causes it to move to the closed position, securing the valve to 90%.

Thanks to the identical frames, the valve systems can be exchanged at any time. Compressed air lines must be installed if you wish to switch to an automatic valve.

Our A.S.K. help prevent environmental disasters. Contact your insurer to see if protecting your sewer system could lead to a reduction in your premium.

Our qualified specialists are available for maintenance, servicing and repair work to ensure that DIBt-compliant approval is maintained during operation and to provide the documentation required by the industrial safety ordinance (BetrSichV).

Manual A.S.K.:

Automatic A.S.K.:

In 2020 our A.S.K. received DIBt approval. Scherzer Umwelttechnik GmbH is an approved specialist according to the Federal Water Act (WHG) and is certified according to ISO 9001:2015.

The A.S.K. prevents environmentally hazardous substances from entering your sewer system. Ask your insurer about reducing your insurance premium.

Your engineering and sales contact:

Ralf Kuchler

T. +49 201 855 14 - 21

F. +49 201 855 14 - 36

r.kuchler@scherzer.net

Your contact:

Michael Koch

T. +49 (0)201 8551 441

F. +49 (0)201 8551 436

koch@scherzer.net

A.S.K. 450 und

A.S.K. 250